Rags old iron rags old iron

Nina Simone, “Rags and Old Iron”

All he was buying was just rags and old iron

I heard that old rag man now making his rounds

He came right to my alley Lord with sorrowful sounds

Crying rags old iron and pulling his cart

Ask him how much he’d give me for my broken heart

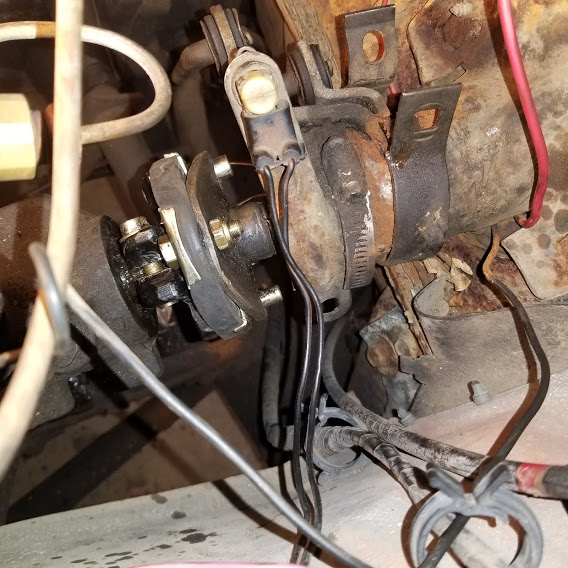

The first major repair that E. and I did on the F-100 was a replacement of the steering rag joint. M. had warned us that this would be a needed fix, and we wanted to get it out of the way quickly since the worn joint made the steering too loose. Before doing the repair, a quarter-turn of the steering wheel produced next-to-no movement in the front wheels–and driving a straight line was a constant back-and-forth adjustment process.

The rag joint doesn’t contain any actual rags; it is made from iron and rubber, sometimes reclaimed from old tires. The edges of the rubber over time show the frayed layering of the original tire, giving the joint a “ragged” appearance. Back in the early 20th century, the center of the joint would have been composed of layers of leather instead. The joint consists of a rubber disc with metal fittings on either side. This is a joint designed to do two things: first, it provides a small amount (just a few degrees) of flexibility in the steering shaft–allowing it to bend very slightly. Second, it isolates the driver from tiny vibrations in the steering system, with the rubber acting as a shock absorber.

The joint replacement ended up being a bear of a job. Before starting, I read several online articles about the process. Then, E. and I watched a video online of someone else changing the rag joint in their F-100. We gathered all the tools we would need, and set about loosening all the bolts that hold the steering column in place. The difficulty in this process wasn’t about stuck bolts, rust, or parts that don’t match. The problem was that, to pull the old joint out and re-install the new one, we had to pull the steering wheel and attached shaft backward–further into the cab–by about 3 inches (the thickness of the rag joint) to create space. Even with everything loose, this was a tough job and all of us (E., her young cousin T., and myself) worked up a sweat.

Everything about this is a process–including the truck itself. The parts don’t do anything unless they are actively engaged with one another, and the way they hook together is important: a rag joint is designed to provide flexibility, and if I replaced it with a solid coupling a) it wouldn’t fit (since there is a slight angle involved) and b) even if it fit, it would be potentially dangerous.

At the end of the day, we have the new rag joint installed and the steering is noticeably tighter than it was before. Oh–and the steering wheel is now cocked 20 degrees to the left when I drive straight. Replacing the steering wheel is on the list, and we will tackle that problem when we get to it.